Digital Twin

- Home

- <

- Digital Twin

PELF

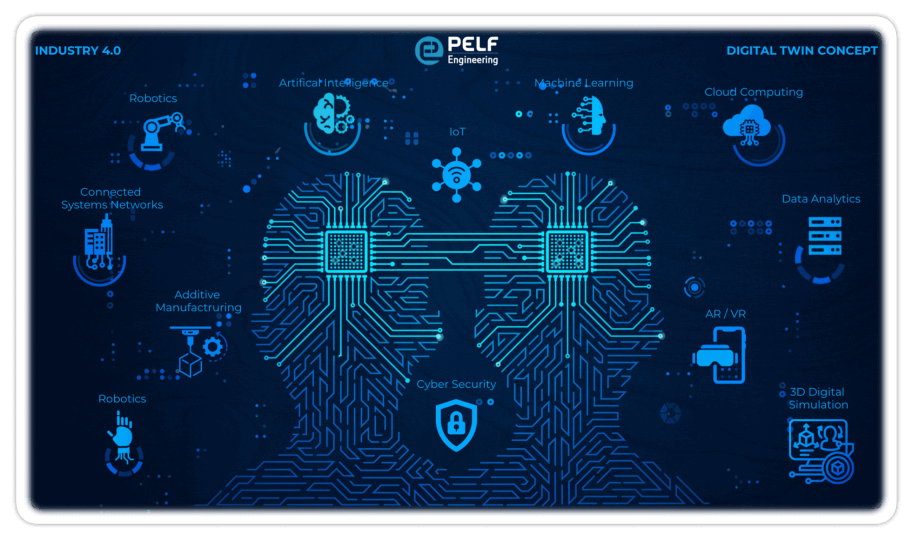

DIGITAL TWIN ECO SYSTEM

PELF engineers work with some of the topmost and global brands to help their clients implement an effective and efficient Digital Twin Eco- System. Our team is equipped with hands-on experience on advanced technologies that form the core for any intelligent manufacturing digital twin solution. The digital twin technology comprises various technologies such as:

loT

Machine Learning

Artificial Intelligence

Robotics

Additive Manufacturing

3D Digital Simulation

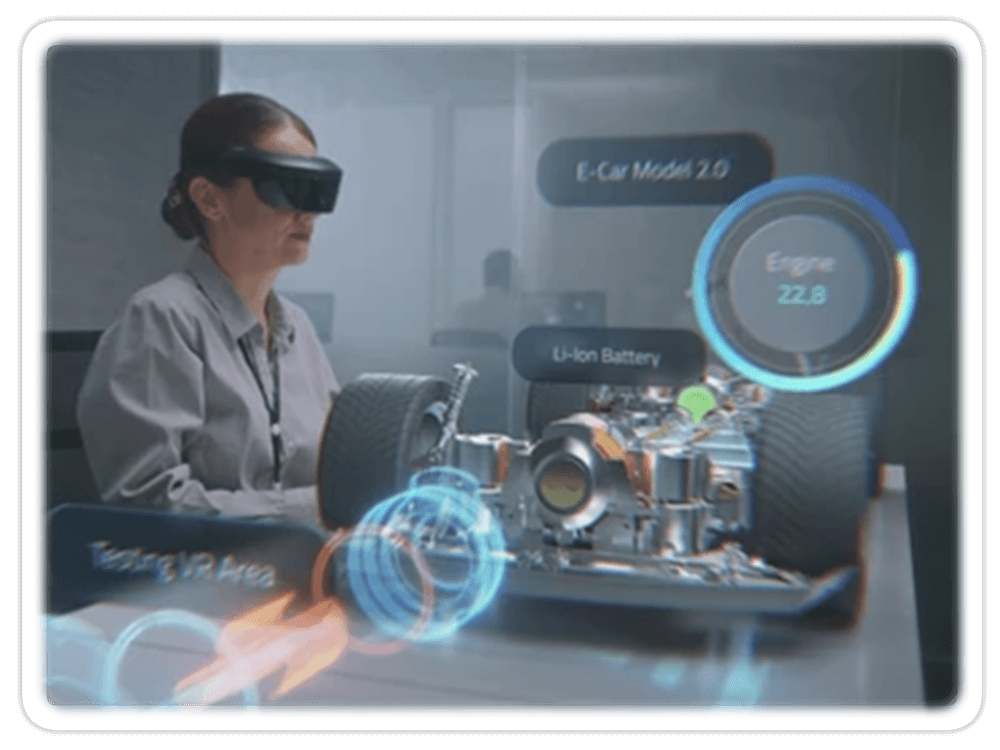

AR / VR

Cloud Computing

Network Integrated Systems

Network Connected Systems

Cyber Security

Data Analytics

Simulation Driven Product Development:

PELF engineers orchestrate the entire DIGITAL TWIN eco-system through its expertise in advanced technologies such as CAE/ CFD/ MBD (Altair, Simulia and Dassault Systèmes suite of products), Simulation, Data Analytics, IoT, Sensors, High Performance Cloud Computing, Artificial Intelligence, Machine Learning, Robotics and more.

Quick and reliable functional and design testing of product, even before the actual physical product is built. This brings down the cost of expensive prototype testing, significantly.

Energy/Sustainability

PELF helps strategize optimal energy consumption. As subject matter experts we identify energy usage patterns and it impact on environment & the society. Our digital twin services helps your business and operational processes to contribute significantly towards your net zero goals.

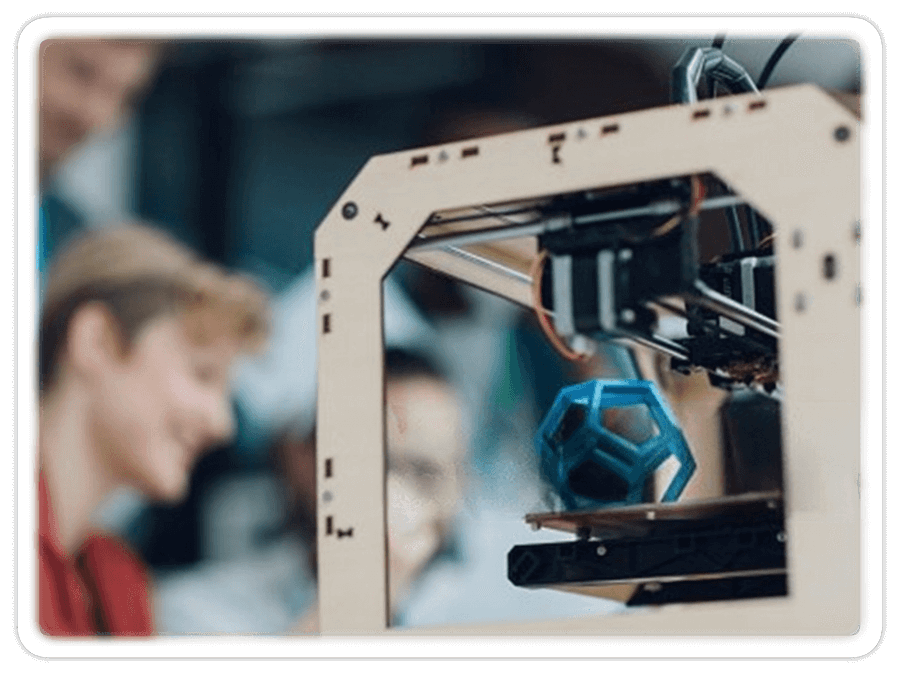

Additive Manufacturing

Services in Plastic, Composite, Metal 3D printing for Prototype mock ups in exhibitions and design checks. We print functional use parts in batch production and for new product design POC.

THE FEEDBACK LOOP

One of the critical elements in the Digital Twin eco-system is the Feedback Loop.

A feedback loop enables feedback from the live physical system. Based on this feedback, the designers and engineers can actually reconfigure parameters, fix problems, identify additional features, etc.

This can then be incorporated in the digital copy to execute change at the physical asset or process level – a mechanism that enables continuous improvement and adaptation based on real-time data and insights.

TYPICAL JOURNEY OF

DIGITAL TWIN IMPLEMENTATION

DIGITAL TWIN

Benefits

Improved visualization & planning

With What You See Is What You Get approach, companies can plan and build digital copies before even starting the manufacturing process, and yet minimize expensive iterations

Iterations Shorter delivery cycles

The digital twin automates the entire operations, based on live data, and predicts any unforeseen challenges. This helps in proactive resolution leading to faster delivery cycles.

Better predictability

The digital twin is an exact replica of the physical asset – in terms of behaviour, performance, properties, capabilities, etc. Therefore, the prediction based on the impact on the digital copy is exceptionally reliable.

Cuts costs, reduces wastes, saves time

Minimize the time, efforts and money in building expensive prototypes. Physical prototypes generally have sizeable loss of materials, require painstakingly complex OEM vendor communication, and are susceptible to human errors and delays. Having a Digital Twin eliminates all of it.

Ensures sustainability

Digital twin helps bring sustainability into the process allowing less power consumption, better production quality, improved efficiency, material enhancement, robust operations and waste reduction.

Real-time monitoring and prediction

With Al / ML based predictive analysis on the live data, companies have the power to change the product and make it future-ready.

Improved collaboration across teams

Based on secure, cloud-based CAE, vendors and partners can collaborate on the same model, thereby reducing the need for communication. Further saves the time required for the vendors to deliver any changes to the physical prototypes.

Drives ever-evolving nature of product

Continuous improvement, innovation-driven and covering the life-time of a product (pre-production, post-production and predictive maintenance & improvement phases), digital twin is the way forward for intelligent manufacturing, improved bottom-line, significantly improved top-line, and overall sustainability of the business, people and the world.

DIGITAL TWIN IS HERE, AND NOW

A digital replica of the actual product in every sense. Design, program, simulate scenarios, test, improve efficiencies, safety, security, comfort and incorporate future-readiness even before building the physical asset.

Digital Twin is a concept, rather than just a technology jargon. An ensemble of advanced technologies is orchestrated in a way that builds the digital replica of the actual physical asset.

DIGITAL TWIN

THE FUTURE IS NOW

ENVISAGE > SIMULATE > PREDICT > CORRECT

KEEP EVOLVING SMARTER

with PELF ENGINEERING's Digital Twin eco-system

Pelf Engineering provides industry-focused, tailored AI/ML services in various emerging trends: Digital Twin, Data Analytics, OEE (Overall Equipment Effectiveness), Energy/Sustainability – Energy utilization and savings, Simulation-driven product development, Additive manufacturing (3D printing).

PELF engineers work with some of the topmost, global brands to help clients implement an effective and efficient Digital Twin Eco- System. Our team is equipped with hands-on experience on advanced technologies that form the core of a robust, intelligent, modern manufacturing set-up.

For more information on PELF Digital Twin solutions and services

- Call us on : +91 99701 66137

- Write to us : info@pelfengineering.com